About

The company was started as a part-time business in 1987 as a one man business, and in 1994 full time. It started small with only two persons, and over the years grown to a success full business with its own building and 13 workers.

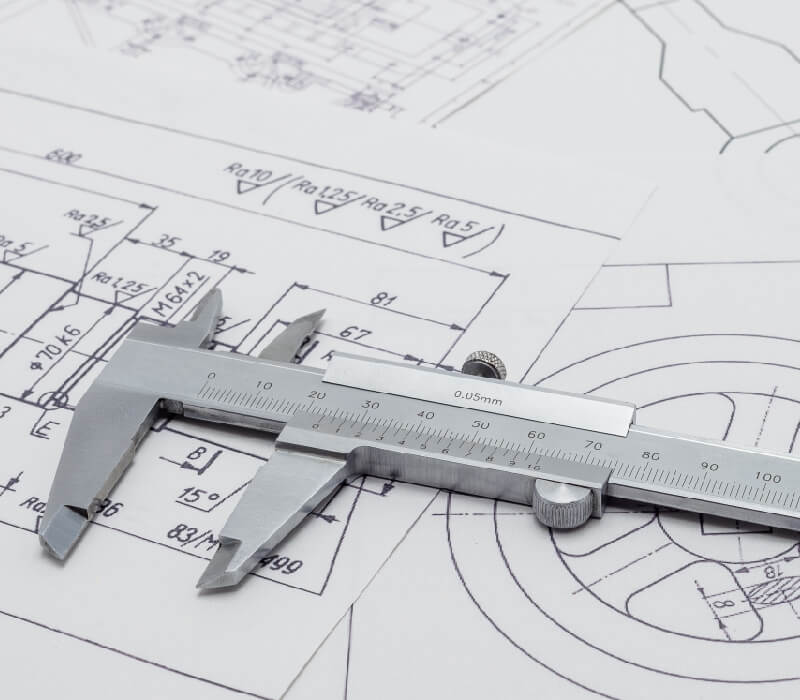

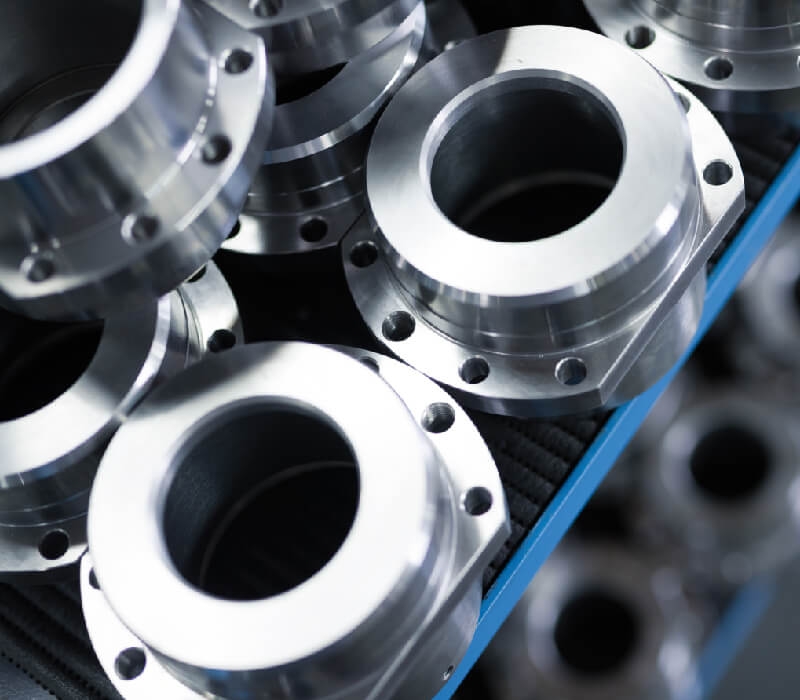

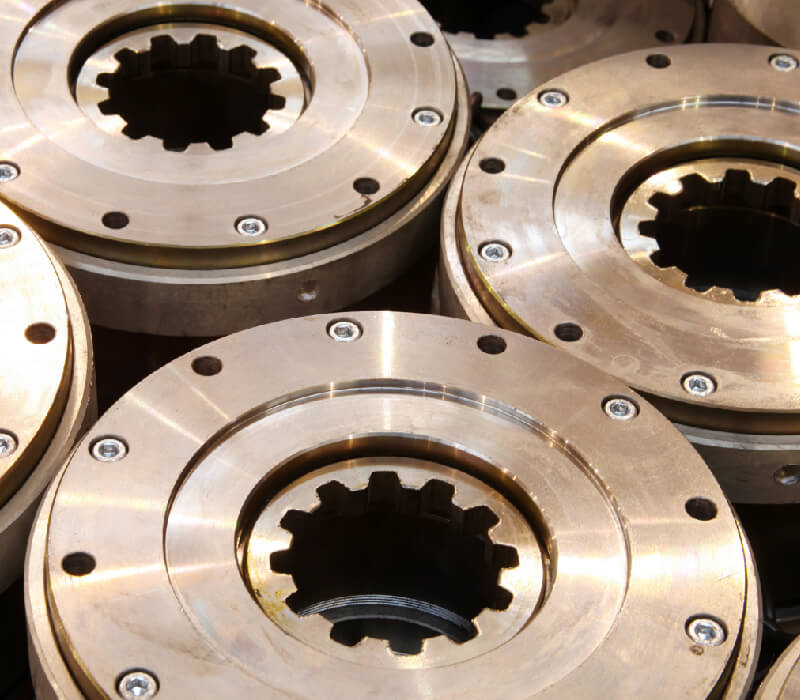

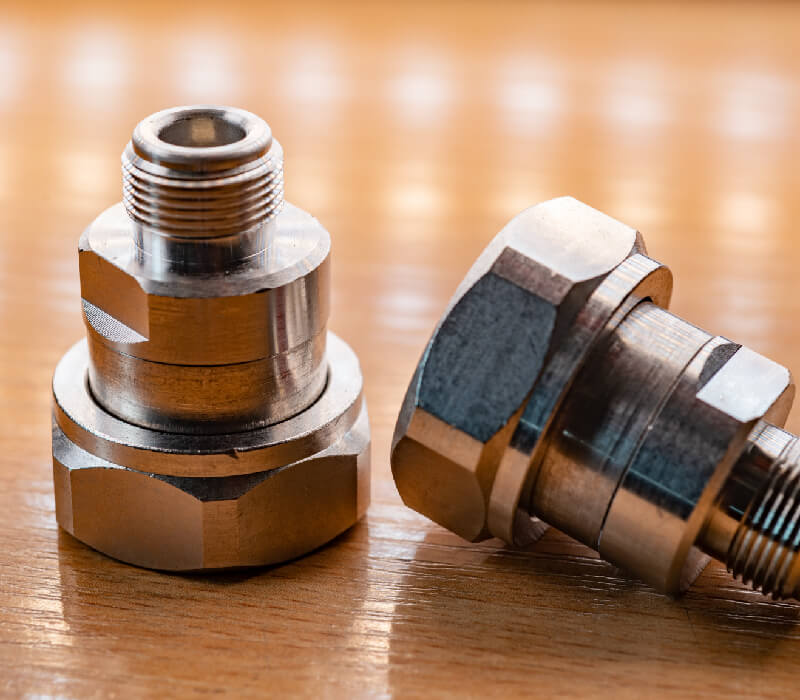

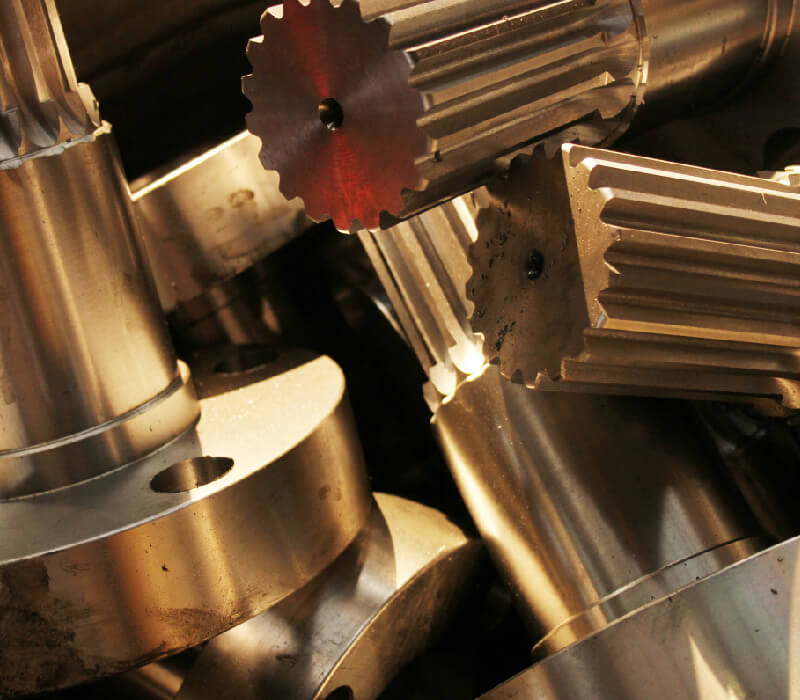

Orion Engineering does mainly general precision manufacturing i.e. milling, turning, grinding, wire cutting, CNC milling and CNC Turning of small to medium parts.

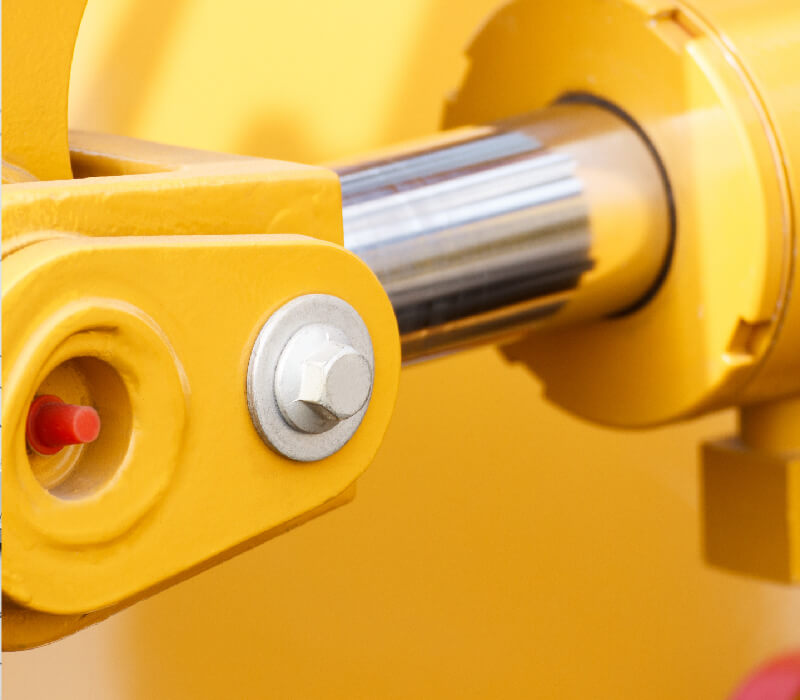

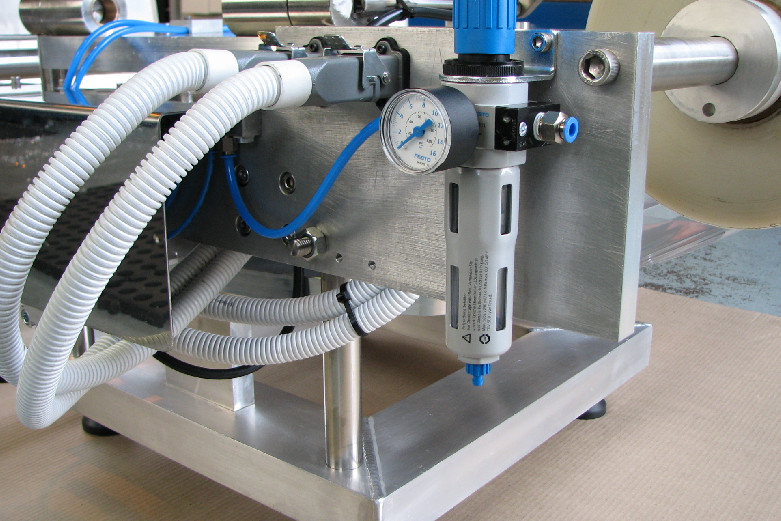

Our expertise and versatility allow us to serve diverse sectors, including the food industry, automotive sector, aerospace, pharmaceutical manufacturing, injection moulding, granite processing, ammunition production, railway systems, and general manufacturing.

We also work with aluminum, stainless steel, tool steel, graphite, mild steel, plastics, and Tufnol. We also offer various advanced coating services including anodizing, nickel plating, metal spray, tungsten spray, and ceramic spray. These treatments can significantly improve the longevity and functionality of your engineered products, providing added value to your projects.

Our Services

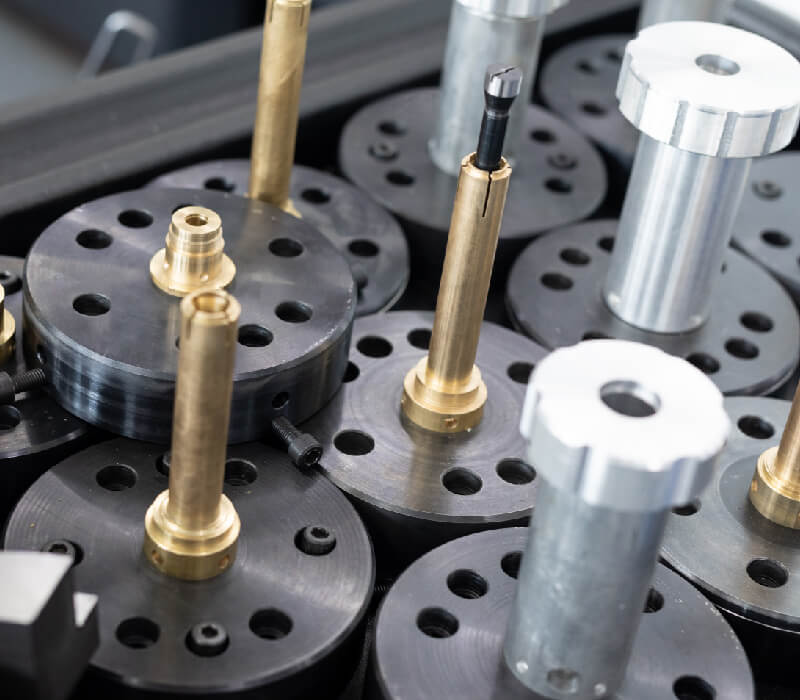

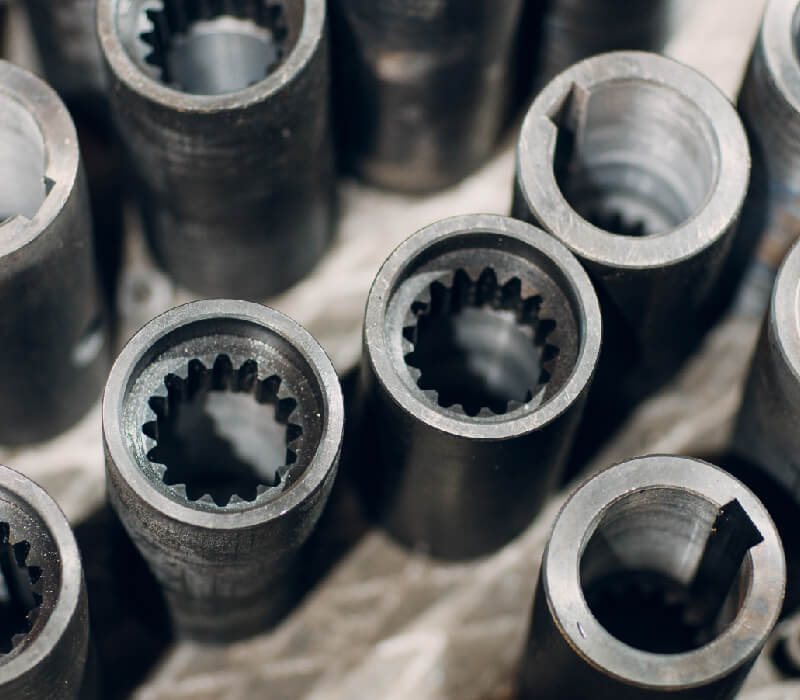

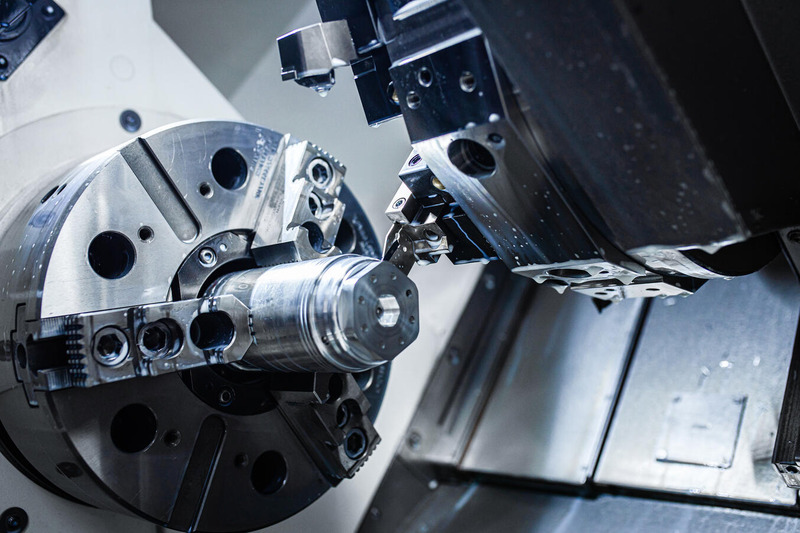

CNC Milling and Turning

Precision machining services using state-of-the-art CNC technology. We offer both milling for complex 3D shapes and turning for symmetrical parts, ensuring high accuracy and repeatability for your custom components.

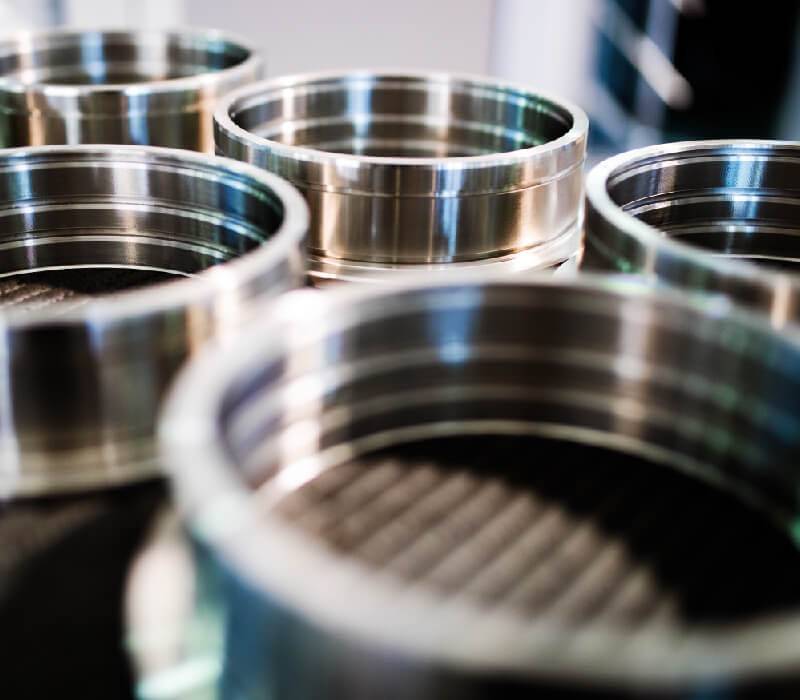

Surface and Cylindrical Grinding

Advanced grinding services to achieve superior surface finishes and tight tolerances. Our surface grinding delivers flat, smooth surfaces, while our cylindrical grinding produces precise round or cylindrical parts for various industries.

Specialized Welding

Expert welding services using CO2 (MIG), TIG, and aluminum welding techniques. Our welders deliver high-quality, durable welds for diverse materials and complex assemblies, meeting rigorous industry standards for both production and custom projects.

Gallery